The efficiency of a hot runner injection system is closely linked to the accuracy of the temperature control. Each proposed device, whether it is a single cavity nozzle controller, a temperature contol up to 240 cavities, a sequential shutter valve control system or a pressure measurement system, is characterized by ease of use and compatibility/integration with any brand of hot runner system. The quality of the temperature control that ensure precision and reliability of the process is the main value. The Agilework P250 positioner is a machine designed to facilitate the operator in the ergonomic positioning of the pieces to be processed, allowing precise control of the height, the angle, and the rotation. On the work table, components can be fixed in different ways, using screws, clamps, a magnetic table, a spindle, or a palletizing system, thus offering a versatility of options for maximum efficiency and precision in the production process. Hot runner systems have become a “must” in the plastics injection industry. The choice of a reliable supplier, equipped with a range of specific products designed according to the type of material processed, the application and the aesthetic result on the molded piece, is more than ever indispensable. In this regard, Sverital offers a specific solution that provides initial technical advice for the study of cavity filling and control of application drawings, installation service and after-sales technical assistance, even in international markets. In addition to undergoing a series of tests that include Ohm value, electrical rigidity, electrical dispersion and insulation resistance, our cylindrical and band resistances are manufactured according to construction criteria that comply with all international protection regulations. The thermocouples selected, on the other hand, are designed to meet most application needs related to injectors and manifolds of hot-runner injection systems. The components offered are the ideal solution for solving and preventing common issues in plastics processing, such as the hot spots caused by excessive heat accumulation and all defects generated by insufficient air and gas venting from the mould cavity. Large-scale productions and the consequent need for product traceability require that even injection moulded items be provided with information and manufacturing characteristics. Fittings and connections made with top quality materials suitable for harsh environments and heavy duty applications. Temperature

control units

Manipulator

mould positioner

Hot runner

systems

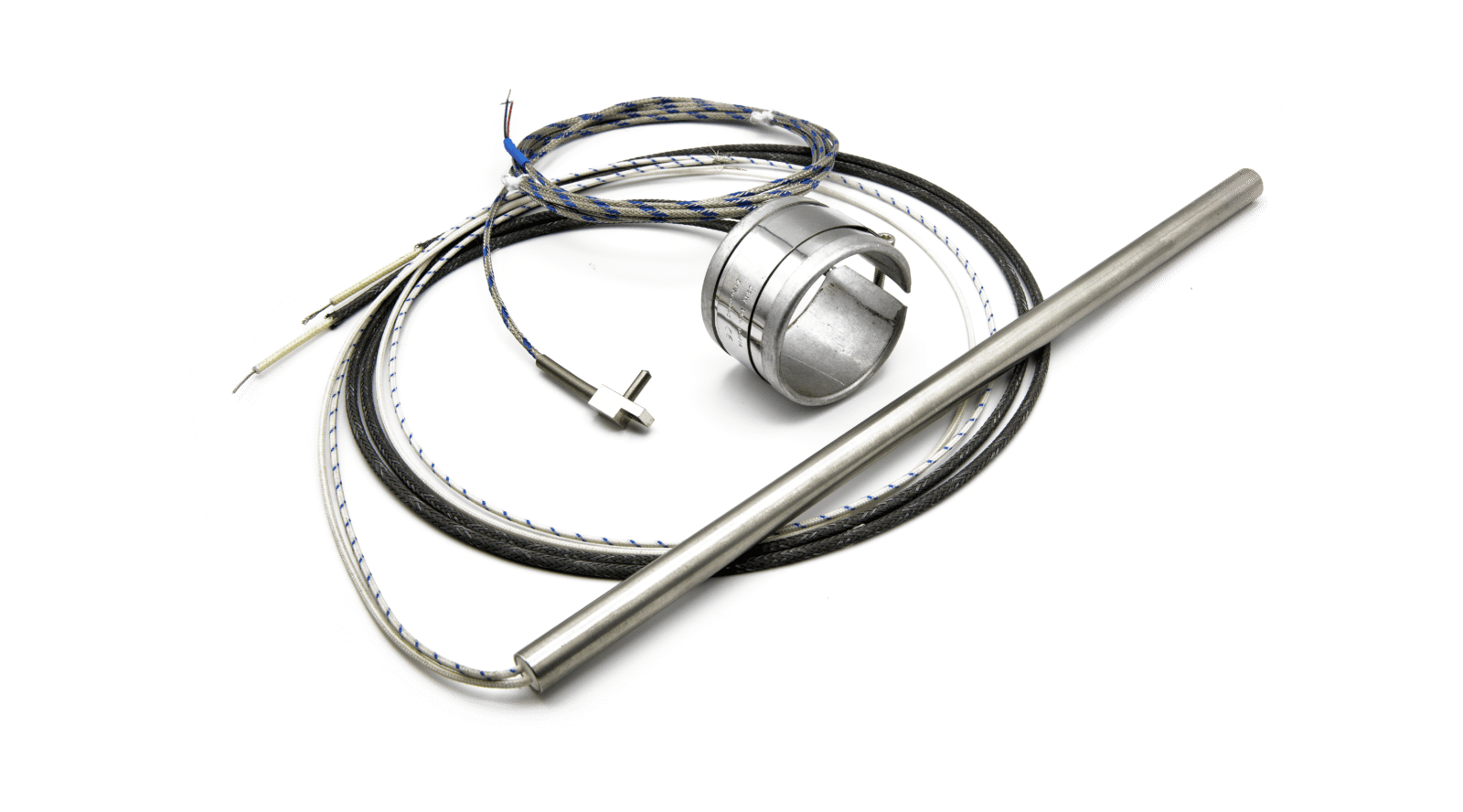

Heaters

and thermocouples

Sintered vents and

mould cooling fountains

Date stamps

and inserts

The infinite variables require a very wide range of inserts and date stamps, such as those proposed by Sverital

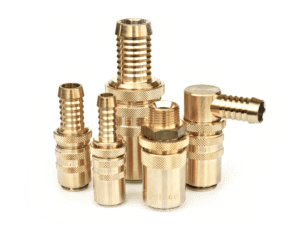

Quick connectors

and nipples